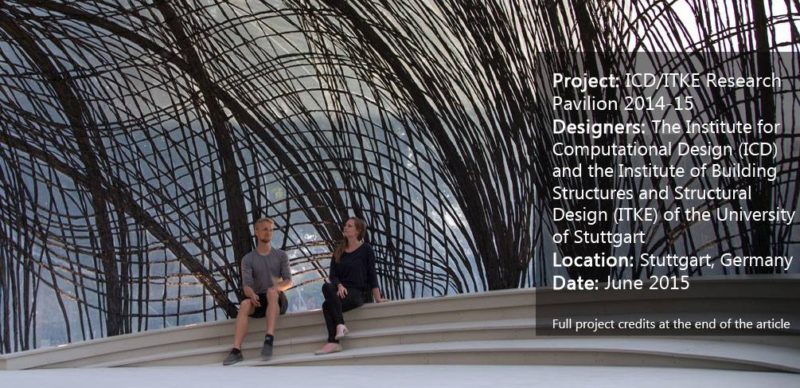

ICD/ITKE Research Pavilion 2014-15, by The Institute for Computational Design (ICD) and the Institute of Building Structures and Structural Design (ITKE) of the University of Stuttgart (Germany), in Stuttgart, Germany. The Institute for Computational Design (ICD) and the Institute of Building Structures and Structural Design (ITKE) of the University of Stuttgart (Germany) are known for their full-scale bionic research pavilions’ experiments, computational design, robotic fabrication strategies, functional integration, and material efficiency. One of the most recent structures at the university is the 2014-15 Research Pavilion, which demonstrates the architectural potential of a novel building method inspired by the underwater nest construction of the diving bell water spider, Agyroneda aquatica.

ICD/ITKE Research Pavilion 2014-15. Photo credit: ©ICD/ITKE Universität Stuttgart

ICD/ITKE Research Pavilion 2014-15

This project is part of a successful series of pavilions that showcase intense studies about simulation and digital fabrication processes, as well as biological research and novel and efficient design strategies for architecture. These building prototypes explore the application of novel computational design, simulation, and fabrication processes in architecture. The new Research Pavilion was studied, designed, and built over one-and-a-half years by researchers and students of architecture, engineering, and natural sciences. The result is a lightweight fiber-composite shell that forms the pavilion with unique architectural qualities, while at the same time being a highly material-efficient structure.

ICD/ITKE Research Pavilion 2014-15. Photo credit: ©ICD/ITKE Universität Stuttgart

The Design

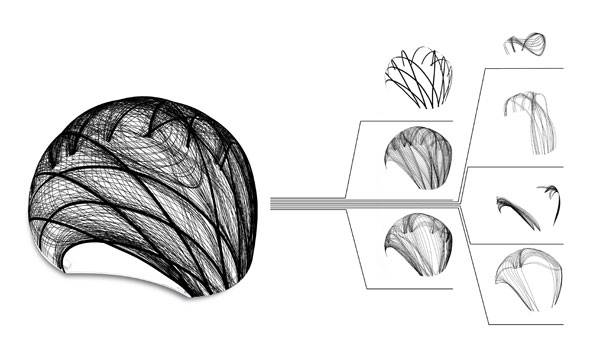

The designs of the ICD and ITKE do not require complex formwork and are capable of adapting to the varying demands of individual constructions. For this pavilion, the design concept is based on the biological construction processes for fiber-reinforced structures; these structures are formed in a highly material-effective and functionally integrated way. The building process of the water spider’s web was analyzed, and the designers transformed the underlying behavioral patterns of the spider and design rules into a technological fabrication process.

Diagram of integrated design criteria. Photo credit: ©ICD/ITKE Universität Stuttgart

The Process

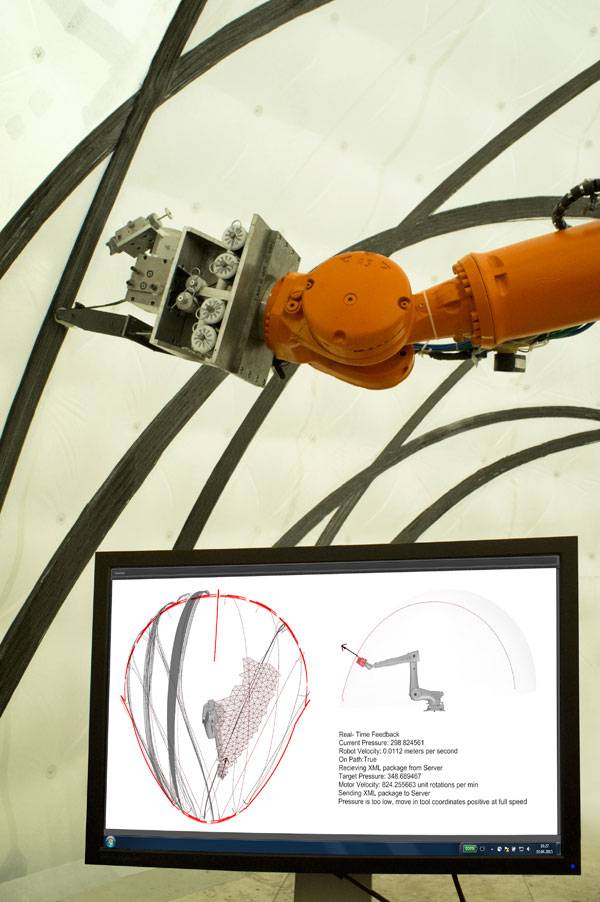

An industrial robot, placed within an air-supported membrane envelope made of ETFE, was used to transform this biological formation into a building. The inflated soft shell is initially supported by air pressure, and, robotically reinforce the inside with carbon fiber and gradually hardened into a self-supporting monocoque structure. The carbon fibers are applied for structural reinforcement and the pneumatic formwork is simultaneously used as functionally integrated building skin. Related Articles:

- ENEL Pavilion: Will Smart Energy Sharing Feed The Planet?

- The Mind-blowing Design of Porsche Pavilion

- Outstanding Bicycle Pavilion in Sanya to House a Velodrome on its Roof

TOP: Conceptual Fabrication Strategy: 1. Inflated pneumatic membrane 2. Robotically reinforce membrane with carbon fiber from inside 3. Stable composite shell . BELOW: Reinforced membrane with hierarchical fiber arrangement. Photo credits: ©ICD/ITKE Universität Stuttgart

The Studies

The designers studied the behavior of the water spider to understand its process of construction. The Agyroneda aquatica spends most of its life underwater, and therefore must construct a reinforced air bubble to survive. First, the spider builds a horizontal sheet web, under which the air bubble is placed. Then, the air bubble is sequentially reinforced by layering a hierarchical arrangement of fibers from within. The result is a stable construction that can resist mechanical stresses, such as changing water currents, to provide a safe and stable habitat for the spider.

Diving Bell Water Spider (Agyroneda aquatica) reinforcing an air bubble from the inside for the ICD/ITKE Research Pavilion 2014-15. Photo credit: ©ICD/ITKE Universität Stuttgart

Various fiber layers robotically placed in ICD/ITKE Research Pavilion 2014-15. Image credit: ©ICD/ITKE Universität Stuttgart

On-site sensor interface for adaptive fiber placement process. Photo credit: ©ICD/ITKE Universität Stuttgart

The Custom Made Robot

This pavilion also required the fabrication of a custom-made robot tool that can place carbon fibers based on integrated sensor data; this became an integral part of the architectural design process.

Materials

ETFE was the suitable material for the pneumatic formwork and integrated building envelope, since it is designed to endure high corrosion resistance and strength over a wide temperature range; its mechanical properties could minimize the plastic deformation during the fiber placement. A high degree of functional integration is achieved through the use of the ETFE film as a pneumatic formwork and building envelope, saving the material consumption of conventional formwork techniques, as well as an additional façade installation. A composite adhesive provides a proper bond between the ETFE film and the carbon fibers. During production, nine pre-impregnated carbon fiber rovings are placed in parallel.

ICD/ITKE Research Pavilion 2014-15. Photo credit: ©ICD/ITKE Universität Stuttgart

ICD/ITKE Research Pavilion 2014-15. Photo credit: ©ICD/ITKE Universität Stuttgart

ICD/ITKE Research Pavilion 2014-15. Photo credit: ©ICD/ITKE Universität Stuttgart

WATCH: ICD/ITKE Research Pavilion 2014-15

– Full Project Credits and Data For ICD/ITKE Research Pavilion 2014-15

Project: ICD/ITKE Research Pavilion 2014-15 Institute for Computational Design: Professor Achim Menges Institute of Building Structures and Structural Design: Professor Jan Knippers Scientific Development: Moritz Dörstelmann, Valentin Koslowski, Marshall Prado, Gundula Schieber, Lauren Vasey Total Area:40m² Internal Volume:130m³ Width:7.5m Height:4.1m Total Construction Weight:260 kg – 6.5kg/m² Address Keplerstr. 11-17, 70174 Stuttgart, Germany Completion date: June 2015

System Development, Fabrication & Construction

WS13/14, SoSe14, WS14/15: Hassan Abbasi, Yassmin Al-Khasawneh, Yuliya Baranovskaya, Marta Besalu, Giulio Brugnaro, Elena Chiridnik, Tobias Grun, Mark Hageman, Matthias Helmreich, Julian Höll, Jessica Jorge, Yohei Kanzaki, Shim Karmin, Georgi Kazlachev, Vangel Kukov, David Leon, Kantaro Makanae, Amanda Moore, Paul Poinet, Emily Scoones, Djordje Stanojevic, Andrei Stoiculescu, Kenryo Takahashi and Maria Yablonina WS14/15: Rebecca Jaroszewski, Yavar Khonsari, Ondrej Kyjanek, Alberto Lago, Kuan-Ting Lai, Luigi Olivieri, Guiseppe Pultrone, Annie Scherer, Raquel Silva, Shota Tsikoliya With the support of: Ehsan Baharlou, Benjamin Felbrich, Manfred Richard Hammer, Axel Körner, Anja Mader, Michael Preisack, Seiichi Suzuki, Michael Tondera In Collaboration With: Department of Evolutionary Biology of Invertebrates, University of Tuebingen Prof. Dr.Oliver Betz. Department of Palaeontology of Invertebrates, University of Tuebingen Prof. Dr.James Nebelsick, Dr.Christoph Allgaier. Institute for Machine Tools, University of Stuttgart Dr. Thomas Stehle, Rolf Bauer, Michael Reichersdörfer. Institute of Aircraft Design, University of Stuttgart Stefan Carosella, Prof. Dr.-Ing. Peter Middendorf Funding: KUKA Roboter GmbH, GettyLab, tat aiRstructures, SGL Carbon SE, Sika Deutschland GmbH, Daimler AG, Walther Spritz- und Lackiersysteme GmbH, Lange+Ritter GmbH, Gibbons Fan Products Ltd, igus® GmbH, Peri GmbH, HERZOG Maschinenfabrik GmbH & Co. KG, AFBW – Allianz Faserbasierter Werkstoffe Baden-Württemberg e.V., Reinhausen Plasma GmbH, Reka Klebetechnik GmbH, HECO-Schrauben GmbH & Co. KG, Airtech Europe S.A., Mack Gerüsttechnik GmbH, RentES, Stahlbau Wendeler GmbH + Co. KG, CARU Containers GmbH, EmmeShop Electronics, STILL GmbH, SH-Elektrotechnik, GEMCO, Zeppelin Rental GmbH & Co. KG More Information: https://icd.uni-stuttgart.de/?tag=RP14 https://www.itke.uni-stuttgart.de/entwicklung.php?id=69 Recommended Reading:

- Urban Design by Alex Krieger

- The Urban Design Handbook: Techniques and Working Methods (Second Edition) by Urban Design Associates

Article by Tahío Avila Return to Homepage

Published in Blog

![Fill for Habitat [Video]](https://land8.com/wp-content/uploads/2022/07/land8-cover-224x150.png)